A new standard for natural compounds production

Redefining how plant actives are produced

Plant-derived compounds have long been at the core of therapeutic and cosmetic innovation. Yet conventional sourcing methods relying on field cultivation remain slow, variable and resource-intensive, which limits both reliability and scalability. Alternatively, petro-sourced ingredients will ingreasingly fall out of compliance regarding environmental standards.

SATIVITRO® was developed to overcome these limitations and promote bio-based sourcing adoption.

Leveraging a natural biomimetic process, our root-based bioproduction is naturally enriched in high-value bioactive molecules. It can deliver innovative plant-based ingredients ensuring batch-to-batch reproducibility and a markedly reduced environmental footprint.

Harnessing Hairy Root Culture

At the heart of SATIVITRO® lies a unique biological system : hairy roots.

These fast-growing plant root tissues are generated through a natural transformation process using Rhizobium rhizogenes.

They combine the advantages of in vitro culture with the full metabolic capacity of the plant, making them uniquely suited to the production of novel and complex natural compounds.

What sets our platform apart is its ability to produce effective and sustainable compounds while adhering to modern biomanufacturing standards and regulatory frameworks.

Continuous growth

Once established, cultures grow vigorously in vitro without external hormones.

High biosynthetic accuracy

Hairy roots synthesize the same complex metabolites as the parent plant.

Engineering-ready

Their genetic profile can be enhanced to modulate biosynthetic pathways and boost productivity.

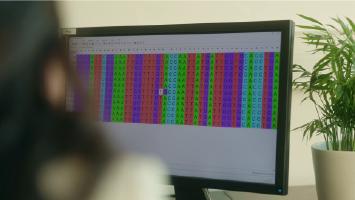

Stability & reproducibility

Genetic and biochemical traits remain stable over time, ensuring consistent production.

How SATIVITRO® works

Our technology uses a flexible, multi-stage process that transforms plant material into a reliable source of high-value bioactives.

Root induction

Using Rhizobium rhizogenes, we initiate root cultures from plant tissue – creating a stable and renewable production system, independent of soil or climate.

Metabolic engineering

With advanced molecular biology tools, we optimize key pathways to boost productivity and enhance the yield of target compounds.

Ingredient Design

Relying on advanced and sustainable downstream processes, we craft the best ingredient revealing the full potential of selected plants.

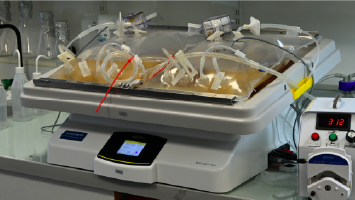

Scalable production

Optimized root lines are transferred into controlled bioreactors, enabling seamless scale-up from research batches to industrial production.